Everything you've ever wanted to know about swabs

Everything you've ever wanted to know about swabs

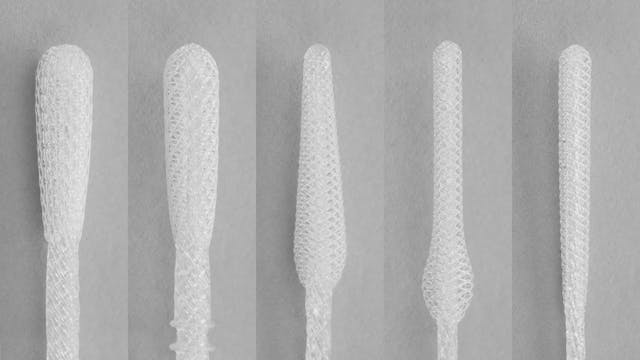

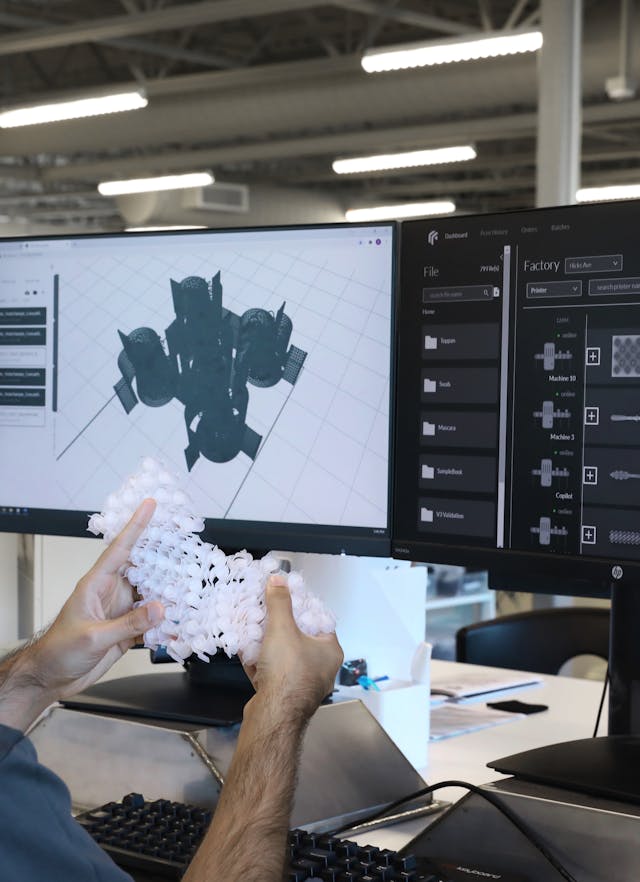

Over the past year and a half, you may have found yourself with a swab up your nose while getting tested for COVID-19. But did you know that the cotton swab was invented in the 1920s? Or that the microstructures of the swab tip can be optimized with algorithms? Read on to learn more about different varieties of swabs, and how innovations in swab technology can lead to improved public health.

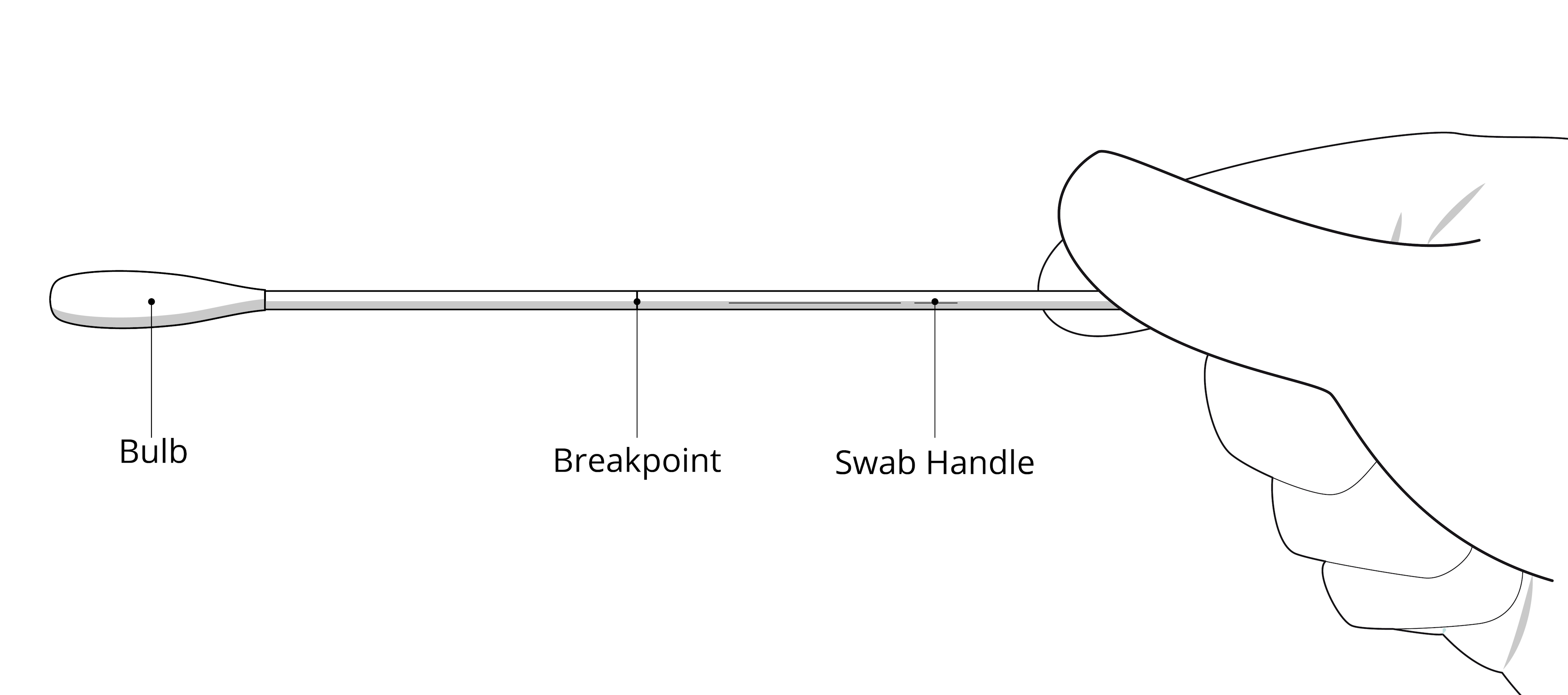

Components of a Swab

Swabs are constructed in a number of different ways to serve a diverse array of purposes. For example, some swabs need to be flexible to reach small cavities while others need to be brittle in order to exert force when collecting samples. Fun Fact: the first modern cotton swab was invented in 1923 by a Polish-American man named Leo Gerstenzang. Reportedly, the invention was inspired by his wife who cleaned her ears with toothpicks. Swabs have come a long way since then. There are many different kinds of swabs each with their own characteristics and advantages.

Types of Swabs

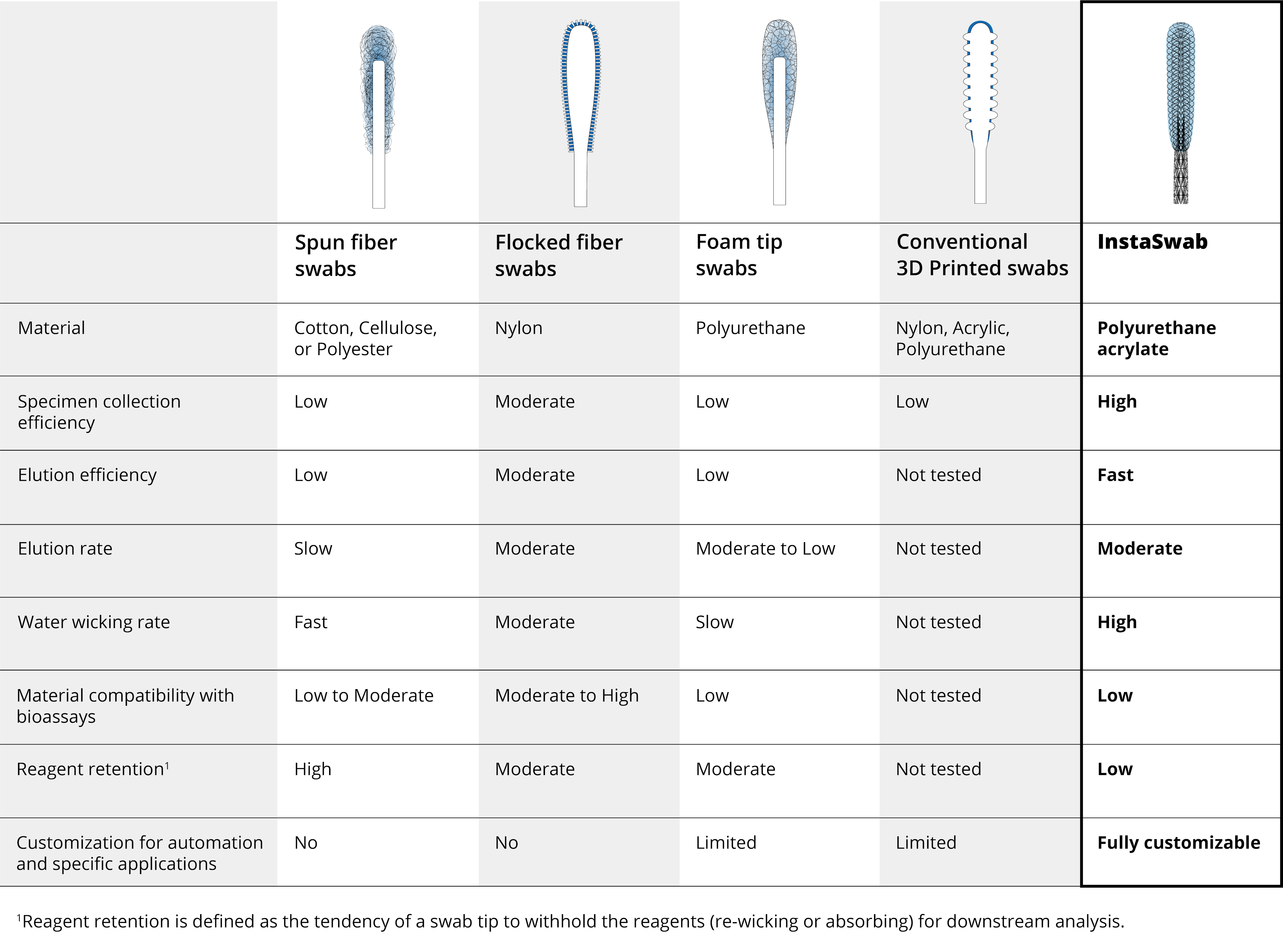

Here is an overview detailing characteristics of some of the most common varieties of swabs:

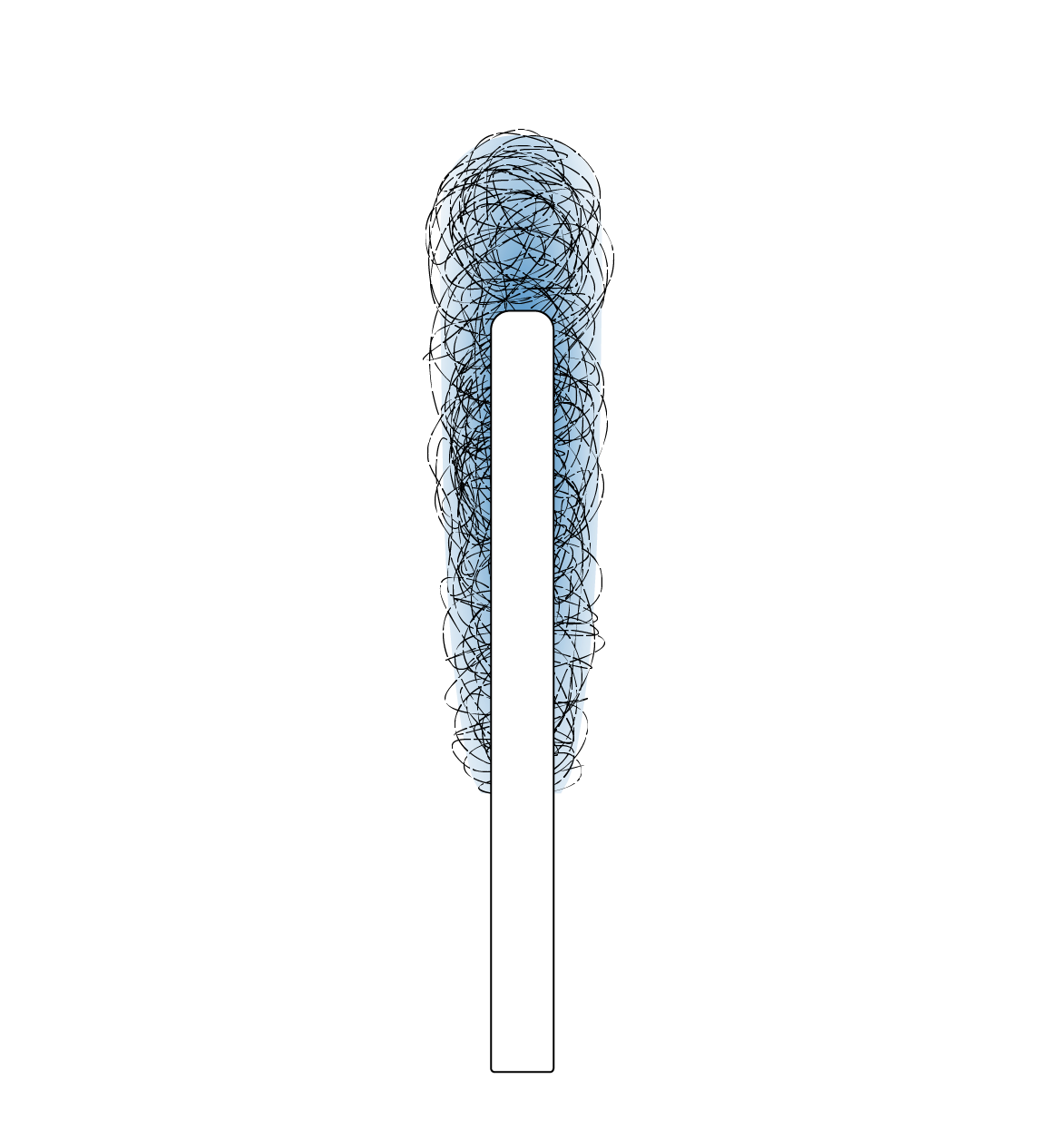

Spun Fiber Swabs are made of cotton, cellulose, or polyester. Their specimen collection efficiency is low, as is their elution efficiency. Their water wicking rate is fast. They have low to moderate compatibility with bioassays. Their reagent retention is high. They are not able to be customized for automation and specific applications.

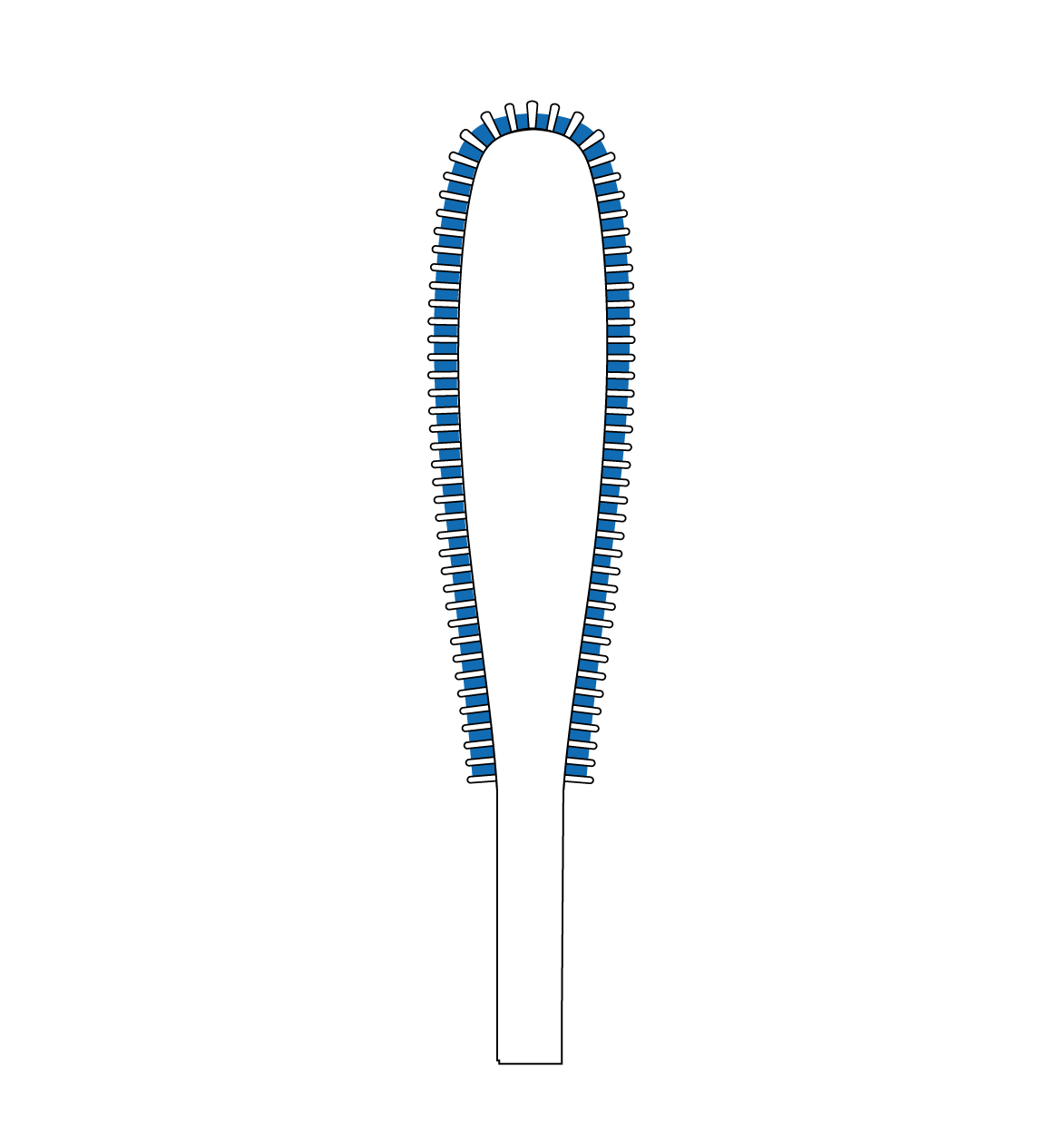

Flocked Fiber Swabs are created from nylon. They have moderate specimen collection efficiency and elution efficiency as well as a moderate elution rate. They have a moderate water wicking rate and moderate reagent retention. They have a moderate to high material compatibility with bioassays. They cannot be customized for specific applications.

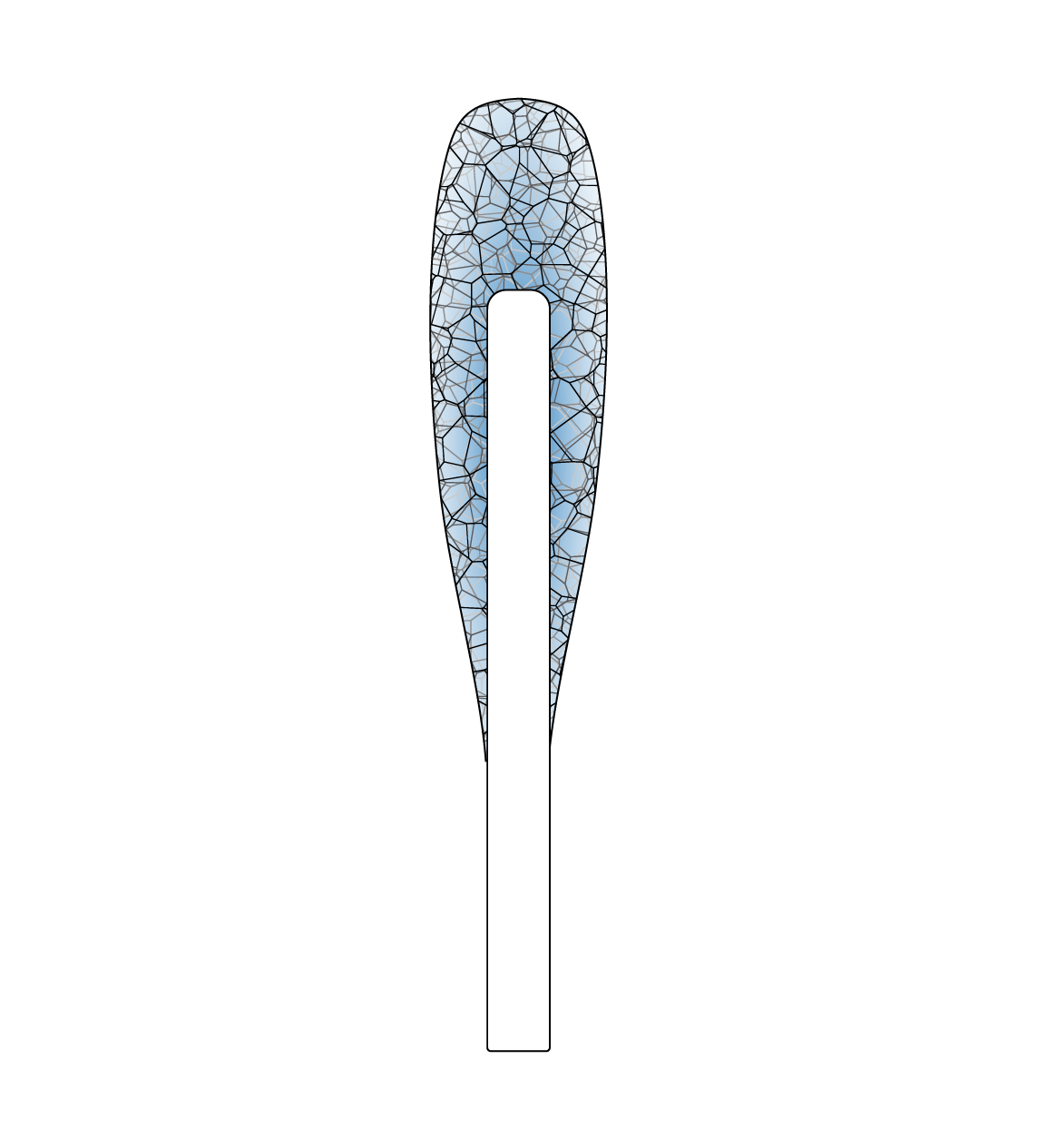

Foam Tip Swabs are made of polyurethane. They have low specimen collection efficiency, low elution efficiency, and a moderate to low elusion rate. They have a slow water wicking rate and low compatibility with bioassays. They have moderate reagent retention. They can be customized for automation and specific applications, but only in a limited way.

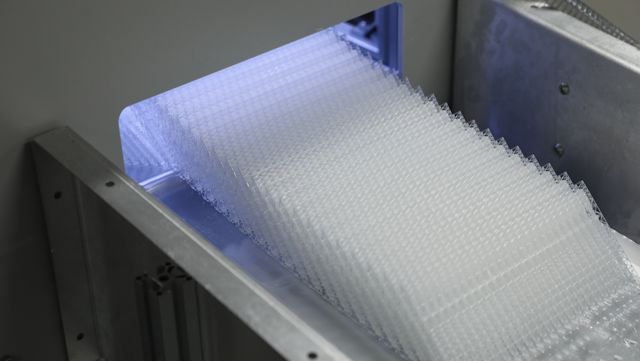

Conventional 3D Printed Swabs are constructed with nylon, acrylic, or polyurethane. They can be produced quickly in small quantities. However, they have low specimen collection efficiency and limited customization for automation and specific applications. Other characteristics of conventional 3D printed swabs are still limited.

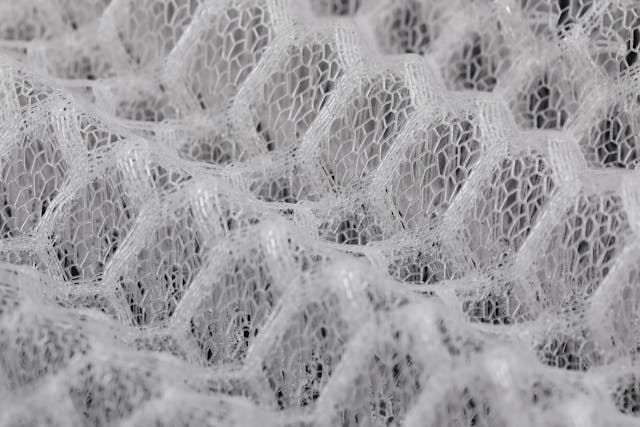

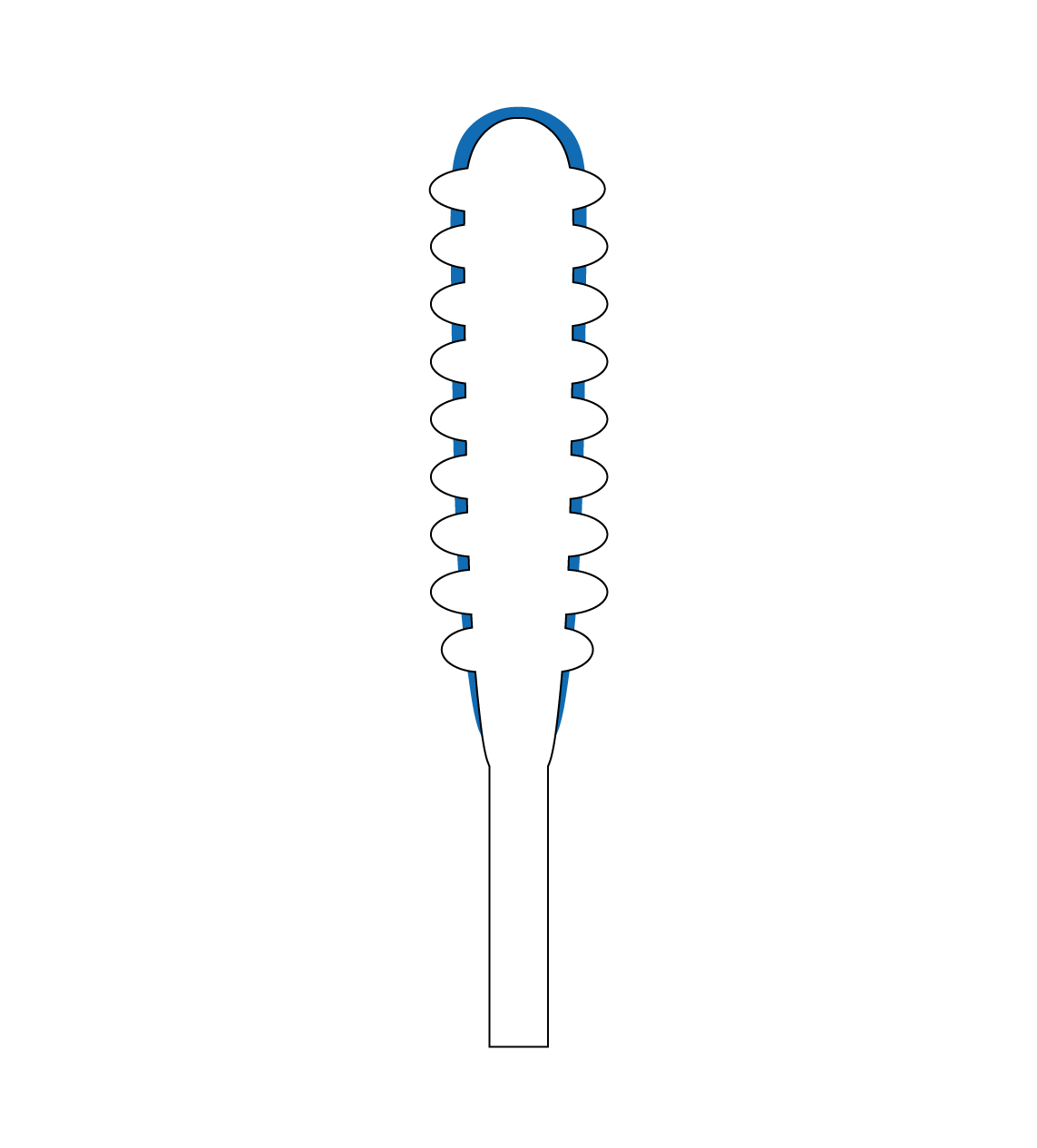

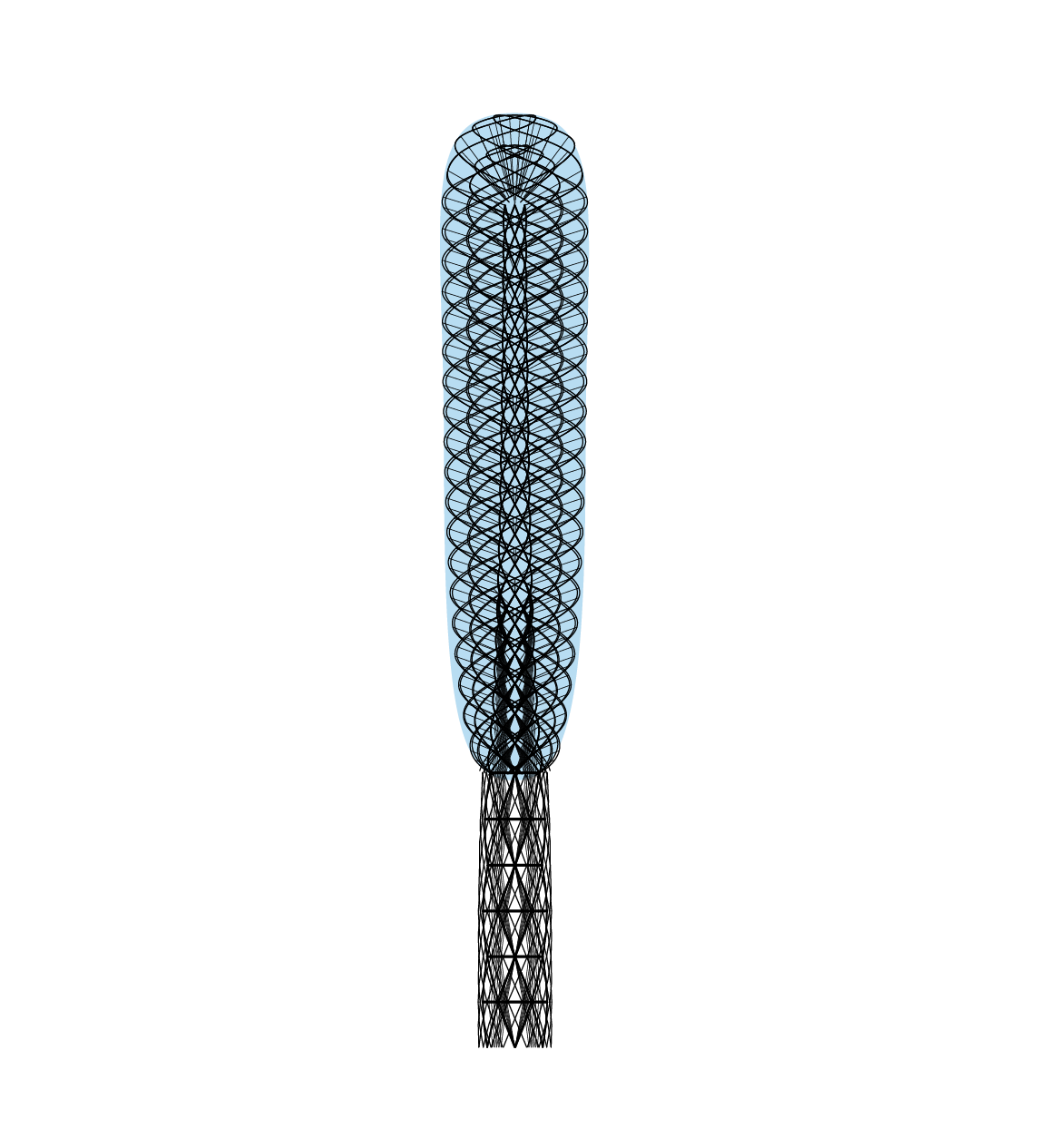

InstaSwabs are created with polyurethane acrylate. Their specimen collection efficiency and elution efficiency is high. They also have a fast elution rate and a moderate water wicking rate. Their material compatibility with bioassays is high and their reagent retention is low. They are fully customizable for automation and specific applications.

Why Swabs Matter

Improved swabs lead to improved public health. Technological advances in swabs allow diseases to be detected quickly so that they can be treated and contained. The COVID-19 pandemic has highlighted just how important it is to have fast, reliable, safe testing for diseases. Swabs are a huge component of this. OPT is committed to combating COVID-19 and other diseases by providing the world with the best possible swabs.